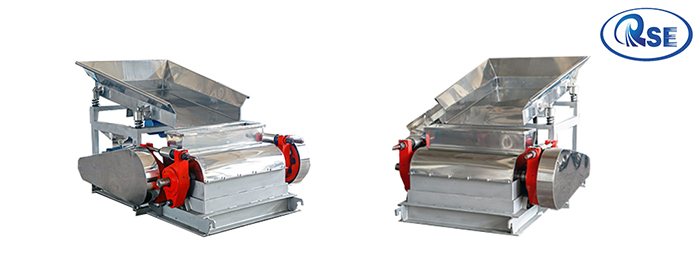

The Salt Roll Crusher Machine is engineered for efficient and effective salt crushing. It is designed to handle bulk salt and reduce it to the desired granule size with minimal fine powder generation. This machine is particularly suitable for salt processing operations where precise control over particle size is crucial.

Key Features

- Simple Structure:

- Benefit: The straightforward design ensures ease of maintenance and operation. Fewer moving parts translate to reduced wear and tear, and increased reliability.

- Compact Machine Body:

- Benefit: The compact size makes it ideal for installation in space-constrained environments. It also contributes to reduced overall machinery footprint and operational cost.

- Reliable Operation:

- Benefit: Built with high-quality materials and engineering, the machine delivers consistent performance, reducing downtime and maintenance requirements.

- Convenient Adjustment:

- Benefit: The roll crusher features an adjustable crushing clearance, allowing for fine-tuning of the particle size to meet specific production needs.

- Minimal Fine Powder Generation:

- Benefit: Designed to produce minimal fines, ensuring that the end product meets quality specifications without excessive waste.

Working Principle

The roll crusher operates primarily on the principle of cutting, with auxiliary methods of squeezing and pressing. Here’s how it works:

- Cutting Mechanism:

- Process: The salt is fed into the machine where it is subjected to a cutting action provided by the rolls. This mechanism effectively reduces the size of the salt crystals.

- Squeezing and Pressing:

- Process: In addition to cutting, the machine applies a squeezing and pressing action to further break down the salt crystals, enhancing the crushing efficiency.

- Adjustable Crushing Clearance:

- Feature: The clearance between the rolls can be adjusted and controlled within a specified range. This flexibility allows for the precise control of the salt granule size.

Main Components

- Rolls:

- Design: Equipped with a flute profile that helps in the effective crushing of salt crystals. The rolls are made from durable materials to withstand the crushing forces.

- Adjustment Mechanism:

- Feature: Allows for the modification of the crushing clearance to achieve the desired particle size. This feature is critical for achieving consistent product quality.

- Frame and Housing:

- Design: The machine is built with a robust frame and housing to support the rolls and absorb operational stresses, ensuring stability and longevity.

- Drive System:

- Components: Includes motors and gears that drive the rolls. The system is designed for smooth operation and minimal noise.

Advantages

- Efficient Crushing:

- Benefit: The combination of cutting, squeezing, and pressing ensures thorough and efficient reduction of salt crystals.

- Adjustable Settings:

- Benefit: The ability to adjust the crushing clearance provides flexibility in achieving different granule sizes, accommodating varying production requirements.

- Low Maintenance:

- Benefit: The simple structure and durable components reduce the need for frequent maintenance and repairs.

- High Reliability:

- Benefit: Designed for continuous operation with minimal downtime, enhancing overall production efficiency.

Applications

- Salt Processing: Ideal for crushing bulk salt into smaller granules for further processing or packaging.

- Food Industry: Suitable for applications where controlled particle size is essential.

- Chemical Industry: Used in various chemical processing operations requiring salt.

Installation and Maintenance Tips

- Installation:

- Site Preparation: Ensure the installation area is clean, level, and has adequate space for operation and maintenance.

- Setup: Follow manufacturer guidelines for installation, including alignment of rolls and connection of the drive system.

- Maintenance:

- Regular Cleaning: Keep the machine clean to prevent buildup of salt residue, which can affect performance.

- Inspection: Regularly check the condition of the rolls and adjustment mechanisms for wear and tear.

- Lubrication: Apply lubricant to moving parts to ensure smooth operation and reduce friction.

Why Choose Our Salt Roll Crusher Machine?

Our Salt Roll Crusher Machine offers a combination of efficiency, reliability, and flexibility, making it an ideal choice for salt processing applications. With its advanced cutting mechanism and adjustable settings, it delivers consistent results and high-quality output, contributing to improved production efficiency and product quality.