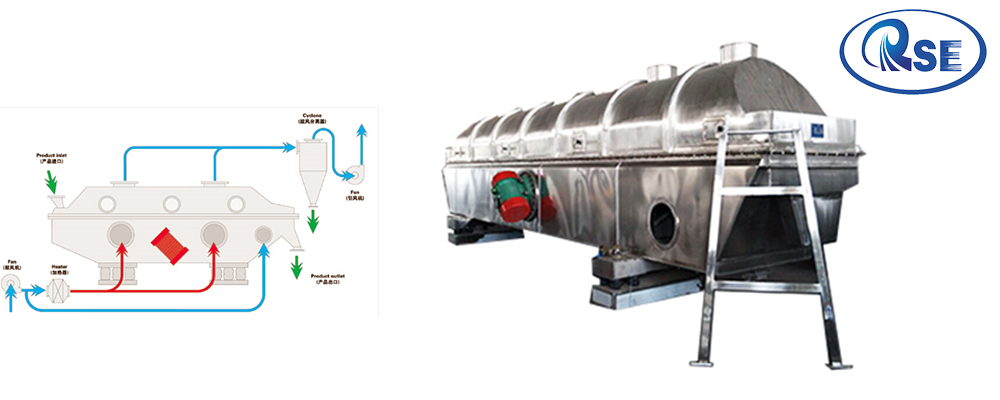

The ZLG Series Salt Vibrating Fluid Bed Dryer is engineered to meet the demands of modern salt production, providing a reliable solution for reducing the moisture content of salt products. The dryer operates under the principles of fluidization and vibration, combining these methods to enhance the drying process and achieve optimal results. Key features of the ZLG Series include its adherence to GMP standards, use of high-quality stainless steel materials, and continuous operation capability.

The material has been feed into the salt vibrating fluid bed dryer, under the dual function of the vibration and air flow, the material move along the fluid bed as throwing forward continuously. Hot air upward through the fluid bed and wet materials from the heat after the exchange, after the cyclone dust emissions from dry materials from discharging from the discharging end.

Key Features

- Fluid Bed Drying Technology

- Description: The ZLG Series uses fluid bed drying technology, where the salt is fluidized by hot air and vibration.

- Functionality:

- Vibration and Air Flow: The dryer utilizes both vibration and air flow to move the material along the fluid bed, promoting efficient and uniform drying.

- Hot Air: Hot air rises through the fluid bed, transferring heat to the wet materials and evaporating moisture.

- Continuous Drying Process

- Description: Designed for continuous operation, the dryer ensures a steady flow of material through the system.

- Advantages:

- Efficient Operation: Supports continuous production with minimal interruption, enhancing productivity.

- Consistent Quality: Provides uniform drying, resulting in a consistent product quality.

- GMP Standard Compliance

- Description: The dryer is built to meet Good Manufacturing Practice (GMP) standards, ensuring compliance with industry regulations and quality requirements.

- Advantages:

- Regulatory Compliance: Meets the stringent requirements for safety, hygiene, and quality in pharmaceutical and food industries.

- Enhanced Safety: Ensures that the equipment and processes adhere to best practices for manufacturing and handling.

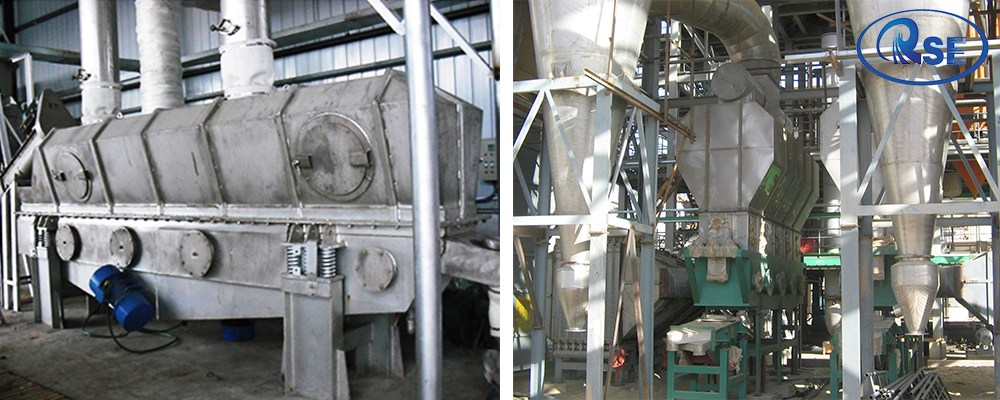

- High-Quality Stainless Steel Construction

- Description: Constructed from stainless steel 304 and 316L, the dryer is resistant to rust and corrosion.

- Advantages:

- Durability: Provides long-term reliability and performance, even in challenging operating conditions.

- Ease of Maintenance: The stainless steel construction facilitates easy cleaning and maintenance, supporting hygiene and longevity.

- Cyclone Dust Collection

- Description: Equipped with a cyclone dust collector to capture and remove dust from the drying process.

- Advantages:

- Clean Operation: Minimizes dust emissions, contributing to a cleaner working environment.

- Improved Air Quality: Helps maintain air quality and reduce environmental impact.

- Adjustable Drying Parameters

- Description: Allows for the adjustment of key parameters such as temperature, airflow, and vibration intensity.

- Advantages:

- Customization: Enables optimization of the drying process based on specific material properties and production requirements.

- Flexibility: Supports the drying of various granular materials with different moisture contents.

Advantages of the ZLG Series Salt Vibrating Fluid Bed Dryer

- High Efficiency:

- Description: Combines vibration and fluidization to enhance drying efficiency.

- Impact: Achieves rapid and uniform drying, improving overall production efficiency.

- Consistent Product Quality:

- Description: Ensures uniform drying and consistent moisture levels in the final product.

- Impact: Provides high-quality salt with predictable properties, meeting industry standards.

- Energy Savings:

- Description: Utilizes hot air and efficient vibration to optimize energy consumption.

- Impact: Reduces operational costs and supports sustainable manufacturing practices.

- Ease of Operation:

- Description: Features user-friendly controls and adjustable parameters for easy operation.

- Impact: Simplifies process management and reduces training requirements for staff.

- Durability and Reliability:

- Description: Constructed from high-quality stainless steel for durability and resistance to corrosion.

- Impact: Ensures long-term performance and reliability, minimizing maintenance needs.

- Environmental Benefits:

- Description: Includes a cyclone dust collector to reduce dust emissions and improve air quality.

- Impact: Supports a cleaner and safer working environment, contributing to environmental protection.

Applications

- Salt Production:

- Uses: Effective drying of salt in large-scale production facilities.

- Benefits: Provides consistent moisture levels, ensuring high-quality salt suitable for various applications.

- Food Industry:

- Uses: Can be used to dry various granular food products, including salt.

- Benefits: Ensures uniform drying and compliance with food safety standards.

- Pharmaceutical Industry:

- Uses: Suitable for drying pharmaceutical powders and granules.

- Benefits: Meets GMP standards and ensures high-quality, safe products.

- Chemical Industry:

- Uses: Can be applied to dry chemical powders and granular materials.

- Benefits: Supports efficient and consistent drying processes for a range of chemical products.

Installation and Maintenance

- Installation:

- Site Preparation: Ensure the installation site has adequate space, ventilation, and infrastructure for the dryer.

- Assembly: Follow manufacturer guidelines for proper assembly and integration with existing production systems.

- Calibration: Calibrate the dryer for accurate temperature, airflow, and vibration settings.

- Maintenance:

- Routine Cleaning: Regularly clean the dryer to prevent residue buildup and maintain hygiene. Pay special attention to the fluid bed and cyclone dust collector.

- Inspection: Conduct periodic inspections to check for wear, damage, and overall performance. Replace worn or damaged parts as needed.

- Lubrication: Apply lubrication to moving parts such as bearings and gears to ensure smooth operation.

- Adjustment: Monitor and adjust drying parameters as needed to maintain optimal performance and product quality.

Safety and Compliance

- Safety Features:

- Overtemperature Protection: Includes safety mechanisms to prevent overheating and potential damage.

- Dust Control: The cyclone dust collector helps reduce dust emissions and maintain a safe working environment.

- Compliance:

- GMP Standards: Designed to meet Good Manufacturing Practice standards, ensuring safety and quality in production.

- Environmental Standards: Incorporates features to minimize environmental impact and support sustainable practices.