Multifunction Stainless Steel Evaporator is suitable for evaporation of the liquid material and recovery of the organic solvent in pharmaceutical, foodstuff and chemical industry etc.

Key Features and Technology

- External Circulation Heating System

- Description: The equipment integrates an external circulation heating system with vacuum concentration technology.

- Advantages:

- Enhanced Evaporation Speed: The combination of external heating and vacuum conditions accelerates the evaporation process, improving throughput.

- Concentration Ratio: Achieves a concentration ratio of over 1.2, suitable for a variety of applications.

- Vacuum Concentration

- Description: Operates under vacuum conditions to concentrate liquid materials.

- Advantages:

- Homogeneous Finished Product: Ensures consistent and uniform product quality.

- Pollution Control: Minimizes contamination risks, maintaining product purity.

- Solvent Recovery: Efficiently recovers organic solvents, reducing waste and operational costs.

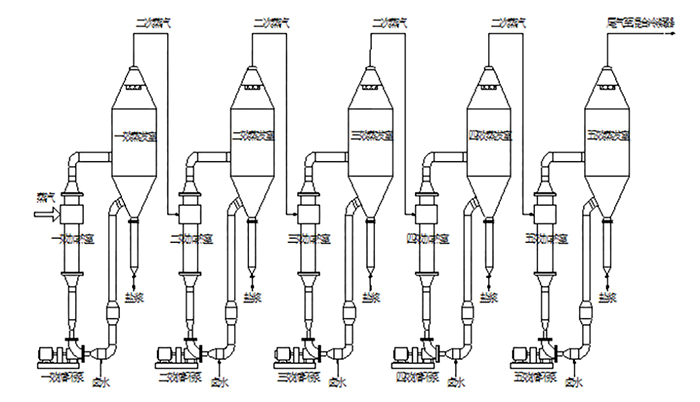

- Triple-Effect Co-Current Evaporation

- Description: Employs a triple-effect evaporation system to maximize the use of steam.

- Advantages:

- Energy Efficiency: Saves up to 60% of energy compared to single-effect evaporators.

- Simultaneous Concentration: Allows for the concurrent concentration of liquid materials in three stages, improving efficiency.

- Quick Opening Heater

- Description: The heater is designed with a quick opening mechanism for ease of cleaning.

- Advantages:

- Simplified Maintenance: Makes cleaning procedures faster and more efficient, reducing downtime.

- Automatic Draining System

- Description: Features an automatic draining system to handle liquid discharge.

- Advantages:

- Labor Reduction: Minimizes manual intervention, lowering operator workload and enhancing operational efficiency.

- PLC Control System

- Description: Equipped with a Programmable Logic Controller (PLC) for automated process control.

- Advantages:

- Automatic Regulation: Controls temperature, pressure, feeding, and discharging processes automatically.

- Precision and Reliability: Ensures accurate control and consistent performance with minimal manual adjustments.

- Multi-Stage Evaporation

- Description: Incorporates multi-stage evaporation (e.g., triple-effect) to enhance efficiency.

- Advantages:

- Maximized Steam Utilization: Utilizes steam more effectively, reducing energy consumption.

- Flexible Operation: Adaptable to different liquid materials and production requirements.

- Heat Transfer Efficiency

- Description: Designed to optimize heat transfer and minimize energy loss.

- Advantages:

- Reduced Energy Costs: Efficient heat transfer lowers overall energy consumption.

- Enhanced Performance: Improves overall operational efficiency.

- User-Friendly Interface

- Description: Features an intuitive interface for easy operation and monitoring.

- Advantages:

- Ease of Use: Simplifies operation and reduces training time for operators.

- Real-Time Monitoring: Provides real-time data on process parameters.

- Safety Features

- Description: Includes safety mechanisms to protect operators and equipment.

- Advantages:

- Overpressure Protection: Prevents damage from excess pressure.

- Leak Detection: Identifies and addresses potential leaks.

Applications

- Pharmaceutical Industry:

- Uses: Concentrating medicinal solutions, recovering solvents.

- Benefits: Ensures high purity and efficiency in drug production.

- Food Processing:

- Uses: Concentrating food extracts, recovering flavoring agents.

- Benefits: Maintains flavor and quality while reducing energy costs.

- Chemical Industry:

- Uses: Concentrating chemical solutions, solvent recovery.

- Benefits: Enhances production efficiency and minimizes waste.

- Environmental Technology:

- Uses: Treatment and recovery of industrial waste liquids.

- Benefits: Supports sustainable practices and reduces environmental impact.

Installation and Maintenance

- Installation:

- Site Preparation: Ensure a clean, level surface with adequate space for the equipment.

- Setup: Assemble and position the equipment according to manufacturer instructions.

- Calibration: Calibrate the system for optimal performance based on production requirements.

- Maintenance:

- Routine Cleaning: Regularly clean the heater, drum, and other components to prevent residue buildup.

- Inspection: Conduct periodic inspections to identify and address wear or damage.

- Lubrication: Lubricate moving parts such as gears and bearings to ensure smooth operation.

- Adjustment: Monitor and adjust operational settings to maintain performance and product quality.