Product Description

Stearic Acid Flakes Making Equipment, as an indispensable key equipment in the modern chemical, cosmetic and pharmaceutical fields, is designed with high efficiency, precision and sustainability in mind, aiming to meet the increasing quality and productivity requirements of the market. The equipment not only integrates industry-leading tablet technology, but also incorporates a number of innovative features that optimize the production process, ensure excellent and stable product quality, and greatly enhance the user experience and ease of operation.

Key Features and Technology

- Internal Spraying Cooling

- Description: The drum is equipped with an internal spraying cooling system to maintain optimal operating temperatures.

- Advantages:

- No Water Accumulation: Prevents issues related to water buildup and ensures efficient cooling.

- Good Cooling Effect: Maintains consistent drum temperature for uniform flake formation.

- Non-Blocking Design: Reduces the risk of blockages and ensures smooth operation.

- Compact and Efficient Structure

- Description: Features a space-saving design with high output capabilities.

- Advantages:

- High Output: Designed to maximize production efficiency.

- One-Man Operation: Allows for operation by a single operator, enhancing labor efficiency.

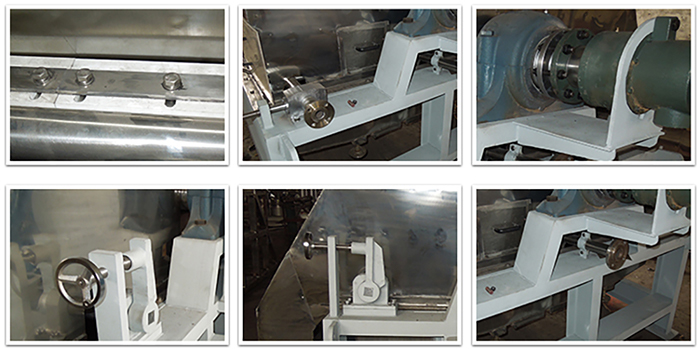

- Multigroup Elastic Scrapers

- Description: Incorporates multiple elastic scrapers with a fine-tuning adjustment mechanism.

- Advantages:

- Convenient Operation: Easy to operate and adjust for different flake thicknesses.

- Flexible Adjustment: Allows precise control over the flake thickness and consistency.

- Enclosed Structure

- Description: Features an enclosed design to minimize exposure to workshop odors and dust.

- Advantages:

- Improved Staff Health: Reduces potential health risks from exposure to airborne contaminants.

- Cleaner Environment: Maintains a cleaner production area and reduces housekeeping requirements.

- Heat Insulation Device

- Description: Equipped with a half-tube tray heat insulation device at the bottom of the trough.

- Advantages:

- Superior Heat Insulation: Enhances energy efficiency and maintains consistent operational temperatures.

- Gear Transmission

- Description: Utilizes a gear transmission system for power transfer and movement.

- Advantages:

- High Transmission Efficiency: Ensures reliable and efficient operation with minimal energy loss.

- Speed Governing Technologies

- Description: Features multiple speed governing options, including frequency conversion and electromagnetism.

- Advantages:

- Easy Drum Speed Control: Allows precise adjustment of drum speed for varying production needs.

- Double Sealed Scrapers

- Description: Includes double sealed scrapers on both sides of the drum for effective material removal.

- Advantages:

- Effective Cleaning: Ensures thorough cleaning of the drum and prevents residue buildup.

- Sealed Flake Thickness Adjustment

- Description: Features a sealed device for adjusting flake thickness.

- Advantages:

- Precise Control: Enables effective control over flake thickness and uniformity for consistent product quality.

- Tempered Glass Window

- Description: Includes a sealed tempered glass window for easy observation.

- Advantages:

- Good Appearance: Enhances the equipment’s visual appeal.

- Convenient Monitoring: Facilitates timely observation and adjustment during operation.

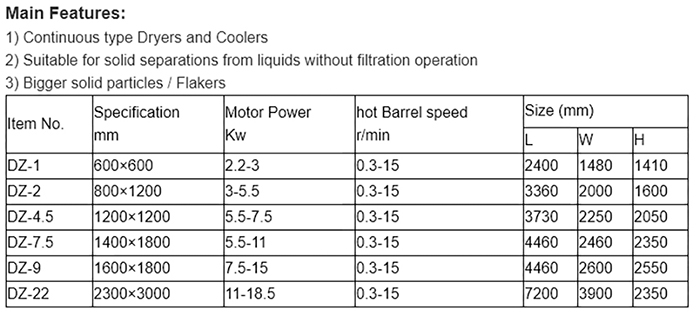

Technical Specifications

- Model: Stearic Acid Flakes Making Equipment

- Capacity: Customizable based on production requirements

- Materials: High-quality stainless steel and corrosion-resistant materials

- Power Supply: 380V/50Hz (customizable to local standards)

- Power Consumption: varies with configuration and capacity

Applications

- Chemical Processing Plants: For producing stearic acid flakes used in various chemical formulations.

- Cosmetic Industry: Ideal for producing stearic acid flakes used in cosmetic products such as lotions and creams.

- Pharmaceutical Industry: Provides high-purity flakes for use in pharmaceutical applications and formulations.

- Industrial Applications: Suitable for use in manufacturing processes requiring high-quality stearic acid flakes.

Installation and Maintenance

- Installation:

- Site Preparation: Ensure the installation area is clean, level, and has sufficient space for equipment and operation.

- Assembly: Follow manufacturer instructions for proper assembly and alignment of components.

- Calibration: Calibrate the equipment to ensure accurate operation and product quality.

- Maintenance:

- Routine Cleaning: Regularly clean the drum, scrapers, and other components to prevent buildup and ensure optimal performance.

- Inspection: Periodically inspect equipment for wear and tear, and replace any damaged parts as needed.

- Lubrication: Apply lubrication to moving parts such as gears and bearings to maintain smooth operation.

- Adjustment: Regularly check and adjust flake thickness settings and other operational parameters to ensure consistent product quality.

Why Choose Our Stearic Acid Flakes Making Equipment?

Our Stearic Acid Flakes Making Equipment combines advanced flaker technology with practical design features to deliver superior performance and efficiency. With its compact structure, effective cooling and flaking capabilities, and user-friendly operation, it provides a reliable solution for producing high-quality stearic acid flakes that meet industry standards.

For more detailed information about the Stearic Acid Flakes Making Equipment, including pricing, technical support, and customization options, please contact our sales team