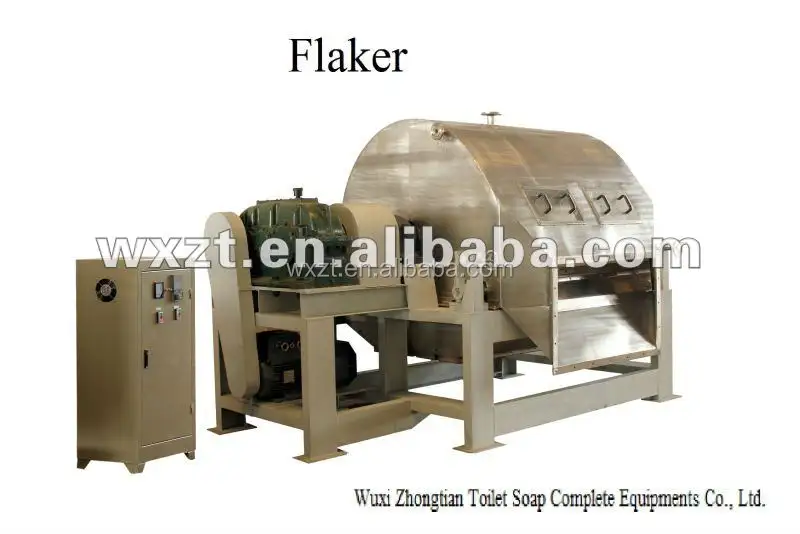

flaker, flake machine, drum flaker, chemical flaker.

We are the professional to be the supplier. Below please find some informations about 2 tons per hour drum flaker:

The Drum Flaker is including: a frame support, electric motor, gear reducer, cooling drum, scraper knife, thickness adjustor, feeding hopper, discharging hopper, stainless steel dedusting Cover etc.

The parts of the Drum Flaker in contact with soap material are 304 stainless steel, and the machine frame support is carbon steel hot spray galvanized.

The drum and material trough of the Drum Flaker are manufactured and inspected as per the specification of the Steel Vessel in normal pressure, the machining, welding and assembling to be made according to the general condition of JB/T4735.1-2009, JB/T 4735.2-2009, JB/T 47003.1-2009.

The drum will be done with the water pressure test under 0.3MPA after finishing the manufacturing.

The data after assembling: radial runout of drum ≤0.1mm, axial transmission±0.2mm.

The contact between scraper and drum should be even, the contact line will be not less than 80% of the whole length. There should be no bumping and abnormal noise when running. The outside shell of the drum should be treated by polishing.

More details:

1) Capacity: 2000kg/h, calculated under the product thickness of 0.5mm, revolution not less than 11rpm etc. (Speed is adjustable, range: 7-18rpm. Thickness of the product: 0.5-2mm)

2) Drum: 1500×1800×12-13mm (304 stainless steel, this thickness is the data after machining). The inside reinforced rings is in material of 20mm carbon steel. Both sides are in 20mm carbon steel laminated with 5mm 304 stainless steel outside).

3) Scraper knife: At the 1/3 part of the lower part,2sets (one as spare part), knife combination, Teflon material lf them. Make it to be adjustable.

4) Feeding hopper: 4mm, there is heating coil at the bottom. Feeding inlet DN40, drain outlet DN40, overflow outlet DN50 (remark: make it to be adjustable up and down). Steam heating outlet DN25.

5) Dedusting cover: 2mm stainless steel 304, 4 view hatches in organic glass, each size: 400x250mm. With DN200 Exhaust opening.

6) Inlet and outlet of cooling water: standard copper rotary connection. The cooling pipe is with spray device.

7) Weight: abt. 4300kg

Main Features

The drum flaker is including: frame support, electric motor, gear reducer, cooling drum,

scraper knife, thickness adjustor, feeding hopper, discharging hopper, stainless steel dedusting Cover etc.

Detailed Images

Applied material for key parts and test standards

—— The parts of stearic acid in contact with soap material is 304 stainless steel,

Machine frame support made of carbon steel hot spray galvanized.

—— The drum and material trough of the flaker is manufactured and inspected as per the specification of Steel Vessel

in normal pressure, the machining, welding and assembling to be made according to the general condition of

JB/T4735.1-2009, JB/T 4735.2-2009,JB/T 47003.1-2009.

—— The drum will be done the water pressure test under 0.3MPA after finishing the manufacturing.

—— The data after assembling: radial runout of drum ≤0.1mm, axial transmission±0.2mm.

—— The contact between scraper and drum should be even, the contact line will be not less than 80% of the whole length. There should be no bumping and abnormal noise when running.

The outside shell of the drum should be treated by polishing.

Pre-sales and after-sales support

Our pre-sales team consists of experienced industry experts who are familiar with market dynamics, understand product characteristics, and are able to provide customers with detailed and professional product consulting. Whether it is product features, performance parameters, or application scenarios, solutions, we will patiently answer to ensure that customers fully understand the product.

We have established a perfect after-sales service system to ensure that we can respond quickly when customers encounter problems. Whether by phone, e-mail or online platform, we will communicate with customers in a timely manner to understand the details of the problem and provide solutions as soon as possible.

Packing & Delivery

Nude packing and wooden case

Delivery within 50 working days