Mekanisk saltproduktionslinje

Vores højkvalitets saltproduktionslinje er et topmoderne system, der er omhyggeligt designet til at forarbejde råsalt fra havet eller søen til renset, færdigt salt af enestående kvalitet. Denne omfattende produktionslinje integrerer avancerede vaske-, knuse- og tørreteknologier for at sikre de højeste standarder for saltets renhed og konsistens.

Processen til fremstilling af salt

trin1

Første vask - Skruesaltvaskemaskine

Formål: At fjerne store urenheder og oprindelige forureninger.

Proces: Råsalt føres ind i en transportsnegl, der omrører og vasker det med vand.

Første vask - Skruesaltvaskemaskine

>>>

trin2

Knusning - Saltvalseknuser

Formål: At reducere saltet til en passende størrelse til videre forarbejdning.

Proces: Saltet knuses mellem to valser, som nedbryder det til den ønskede granulatstørrelse.

Knusning - Saltvalseknuser

>>>

trin3

Sekundær vask - vaskemaskine med omrøring

Formål: At rense saltet yderligere og fjerne finere urenheder.

Proces: Saltet omrøres i en lodret tank med mekaniske knive, der sikrer grundig vask.

Sekundær vask - vaskemaskine med omrøring

>>>

trin 4

Sidste vask - modstrømsvaskemaskine

Formål: At opnå den højeste grad af renhed ved at skylle saltet grundigt. Proces: Salt vaskes ved hjælp af en modstrømsstrøm af vand, hvilket maksimerer kontakt og fjernelse af urenheder.

Sidste vask - modstrømsvaskemaskine

>>>

>>>

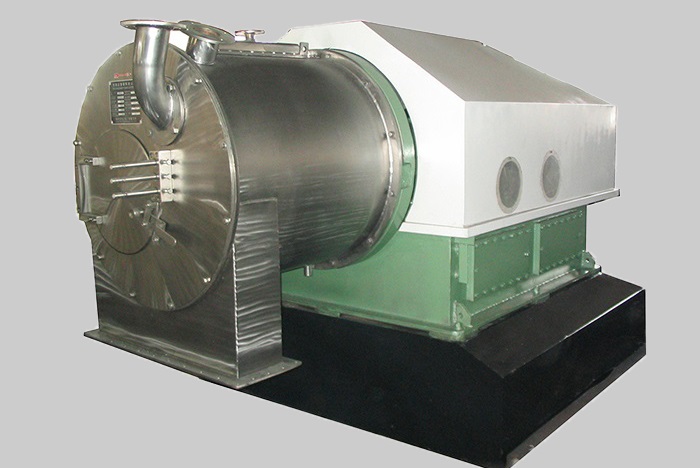

Dehydrering - Saltcentrifuge

trin 5

Dehydrering - Saltcentrifuge

Formål: At fjerne det meste af det resterende vand fra det vaskede salt.

Proces: Salt centrifugeres ved høje hastigheder i en centrifuge for at drive vand ud gennem centrifugalkraften.

>>>

Tørring - Salt vibrerende fluid bed-tørrer

trin 6

Tørring - Salt vibrerende fluid bed-tørrer

Formål: At tørre saltet til et fugtindhold på 0,4%.

Proces: Salt spredes i et vibrerende fluidiseret leje, hvor varm luft passerer igennem og tørrer det jævnt.

>>>

Iodisering - Saltjodiseringsmaskine

trin 7

Iodisering - Saltjodiseringsmaskine

Formål: At tilsætte jod til saltet for at berige det.

Proces: En jodiseringsmaskine tilfører en kontrolleret mængde jod under saltets overførsel fra centrifugen til tørresengen.

>>>

Emballage - Saltpakkemaskine

step8

Emballage - Saltpakkemaskine

Purpose: To package the finished salt for distribution. Process: The dried and iodized salt is packed into bags or containers using automated packaging machines.

Specifications

more information about salt and soap production lines

Model: Mechanical Salt Production Line

Capacity: 0.5 to 50 tons/hour (customizable)

Materials: Stainless steel, corrosion-resistant materials

Power Supply: 380V/50Hz (customizable to local standards)

Maskiner til forarbejdning af salt

Kom i kontakt med os

Have questions or need more information about our salt production solutions? Our team is here to assist you with tailored advice and expert support. Reach out today to learn more about how we can help you achieve top-quality production.

Why Choose RSE Salt Production Line?

High Purity Salt

Multi-stage washing and final iodization ensure the salt meets high purity and quality standards. The refined salt has high purity, a shiny appearance, good free liquidity, and stable iodine content.

Efficient Operation

Each stage of the process is designed for efficiency, reducing processing time and operational costs. Low loss, the loss of NaCl is under 10%.

Customizable Capacity

The production line can be tailored to different capacities (from 0.5 to 50 tons/hour) to meet specific production needs

Durable Construction

Engineered with high-quality, corrosion-resistant materials for long-term reliability and minimal maintenance. The equipment offers a long service life and is easy to operate and maintain.

Integrated Iodization

Seamlessly adds iodine to the salt, meeting nutritional standards without additional processing steps.

Ready to move?

Get a quote now !

Advanced Technology

Combination of Technologies: The integration of wet crushing, dry crushing, and advanced washing methods significantly improves the quality of the salt.