Laundry Soap Finishing Line

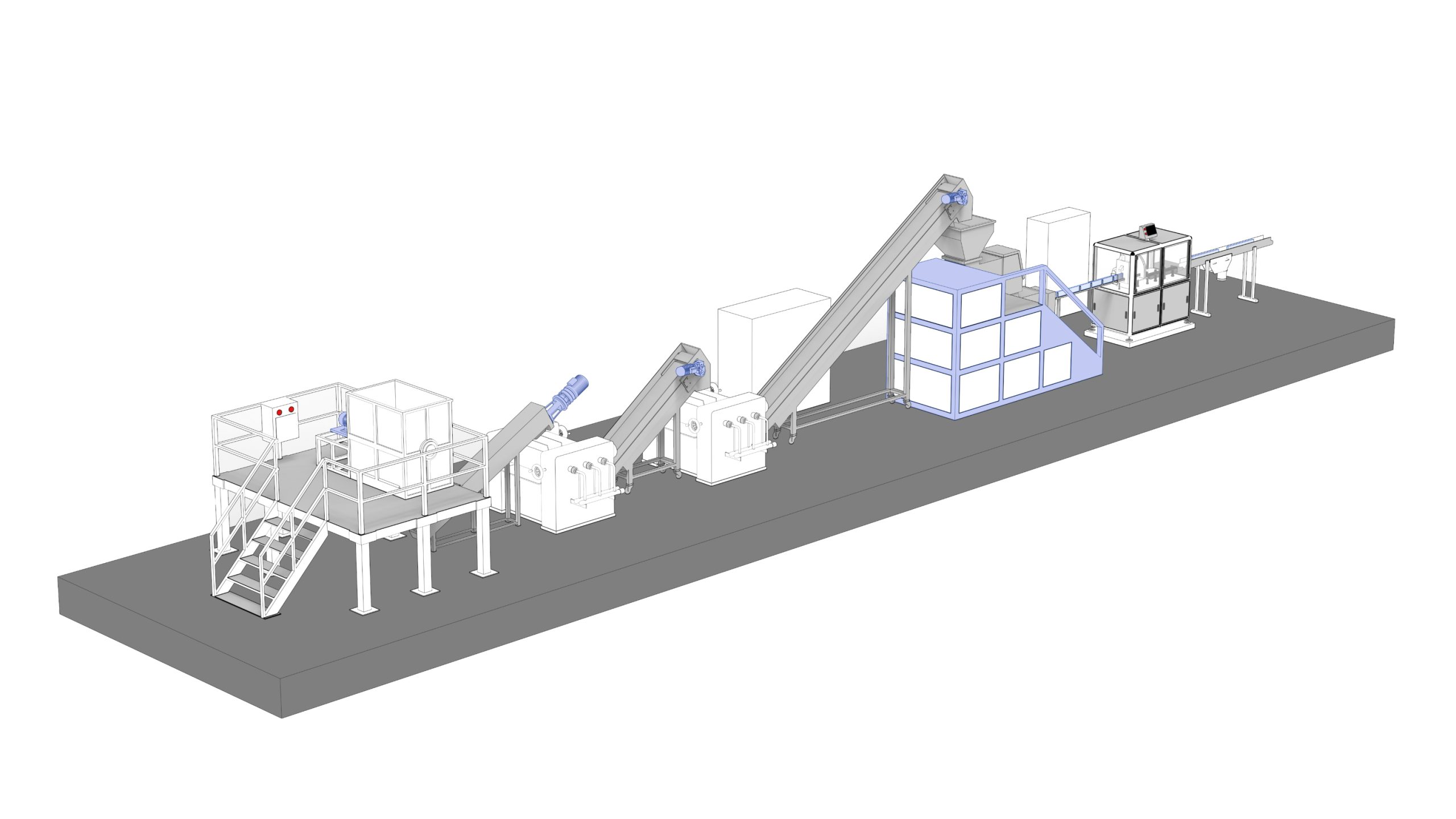

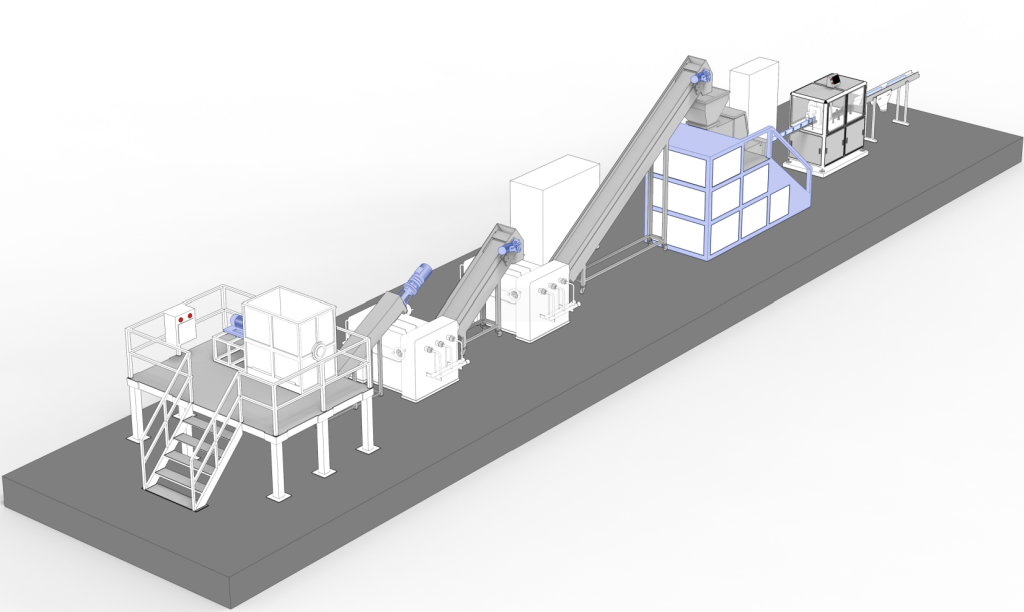

The laundry soap finishing line is the final stage of soap processing. The main soap making machinery includes mixer, roller mill, refiner, plodder, cutting machine, stamping machine.

Complete Solution for Laundry Soap Finishing Line

The laundry soap finishing line is the final stage of soap processing. The main soap making machinery includes mixer, roller mill, refiner, plodder, cutting machine, stamping machine.

Our soap production lines are designed with the diversified needs of our customers in mind. Whether it is a small-scale artisanal workshop or a large-scale industrialized production, we can offer tailor-made solutions. Variations in production capacity from 500kg/h to 2000kg/h can be easily realized by adjusting the configuration and number of equipment, ensuring that production efficiency closely matches market demand.

Comprehensive Solution for Laundry Soap

Our soap production lines are designed with the diversified needs of our customers in mind. Whether it is a small-scale artisanal workshop or a large-scale industrialized production, we can offer tailor-made solutions. Variations in production capacity from 500kg/h to 2000kg/h can be easily realized by adjusting the configuration and number of equipment, ensuring that production efficiency closely matches market demand.

Soap Making Machinery

Soap Mixers

Roller Mill

Soap Refiner

Plow Blade Mixer

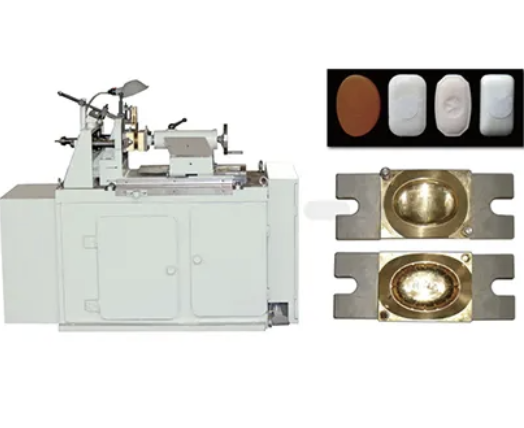

Soap Cutting Machine

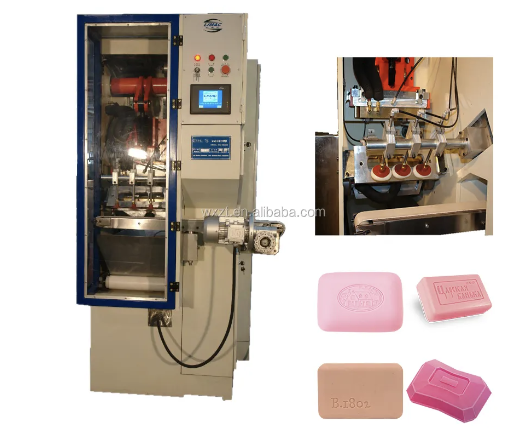

Soap Stamping Machine

Why Choose RSE Laundry Soap Production Line?

High Efficiency

- High Production Capacity: Capable of producing up to 2000 kg of laundry soap per hour, meeting large-scale production needs efficiently.

- Fully Automated Process: Automates the entire production process, from raw material feeding to final soap bar packaging, reducing manual labor and operational costs.

- Continuous Operation: Designed for uninterrupted production, minimizing downtime and maximizing throughput.

Superior Quality

- ISO9001:2000 Certification: Adheres to international quality management standards, ensuring reliable and consistent product quality.

- Advanced Technology: Utilizes cutting-edge mixing, milling, plodding, and cutting technologies to produce uniform and high-quality soap bars.

User-Friendly Design

- Intuitive Control Panel: Features an easy-to-use interface for efficient machine operation and monitoring.

Quick Changeover: Allows for fast and flexible changeover between different soap formulations and sizes. - Low Maintenance: Constructed with durable materials to minimize maintenance needs and extend equipment lifespan.

Versatile Application

- Multiple Soap Types: Capable of producing various types of laundry soap bars, including different formulations and fragrances.

- Customizable: Adjustable settings and interchangeable molds allow for the production of customized soap bars to meet specific branding requirements.

Our Advantage

Our laundry soap manufacturing machinery has won the trust and praise of many customers for its high efficiency, flexibility, and versatility. No matter what your production scale is, we can provide you with the most suitable solution.

Efficient Soap Production

Our laundry soap production line is engineered to provide a comprehensive solution for soap manufacturing. Its advanced features and technology ensure efficient production and superior product quality, making it an essential tool for large-scale soap producers.

Reliable After-Sales

We strictly control the quality of every step from raw material procurement to finished product delivery. At the same time, we provide a full range of after-sales services, including equipment installation and commissioning, technical training, maintenance, and long-term technical support, to ensure that customers have no worries about using the process.

Get in Touch with Us

Have questions or need more information about our soap production solutions? Our team is here to assist you with tailored advice and expert support. Reach out today to learn more about how we can help you achieve top-quality production.