Mechanical Salt Production Line

Our high-quality salt production line is a state-of-the-art system meticulously designed for processing crude sea salt or lake salt into purified, finished salt with exceptional quality. This comprehensive production line integrates advanced washing, crushing, and drying technologies to ensure the highest standards of salt purity and consistency.

Salt Making Process

step1

First Washing – Screw Salt Washing Machine

Purpose: To remove large impurities and initial contaminants.

Process: Crude salt is fed into a screw conveyor that agitates and washes it with water.

First Washing – Screw Salt Washing Machine

>>>

step2

Crushing – Salt Roller Crusher

Purpose: To reduce the salt to a suitable size for further processing.

Process: The salt is crushed between two rollers, which break it down to the desired granule size.

Crushing – Salt Roller Crusher

>>>

step3

Secondary Washing – Stirring Washing Machine

Purpose: To further clean the salt and remove finer impurities.

Process: The salt is stirred in a vertical tank with mechanical blades, ensuring thorough washing.

Secondary Washing – Stirring Washing Machine

>>>

step4

Final Washing – Countercurrent Washing Machine

Purpose: To achieve the highest level of purity by thoroughly rinsing the salt. Process: Salt is washed using a countercurrent flow of water, maximizing contact and impurity removal.

Final Washing – Countercurrent Washing Machine

>>>

>>>

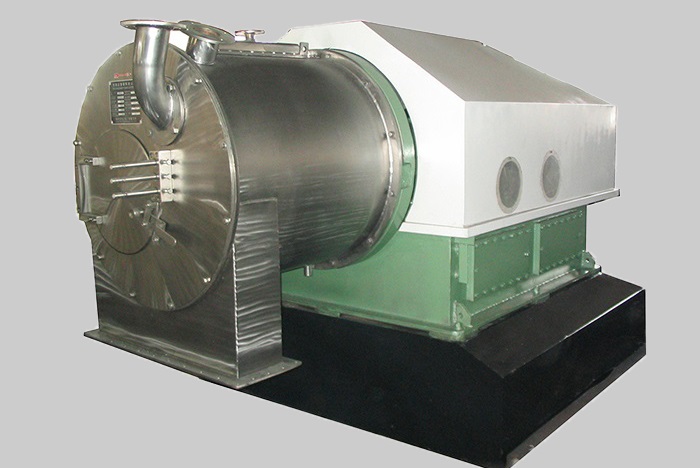

Dehydration – Salt Centrifuge

step5

Dehydration – Salt Centrifuge

Purpose: To remove most of the remaining water from the washed salt.

Process: Salt is spun at high speeds in a centrifuge to expel water through centrifugal force.

>>>

Drying – Salt Vibrating Fluid Bed Dryer

step6

Drying – Salt Vibrating Fluid Bed Dryer

Purpose: To dry the salt to a moisture content of 0.4%.

Process: Salt is spread in a vibrating fluidized bed where hot air passes through, drying it evenly.

>>>

Iodization – Salt Iodization Machine

step7

Iodization – Salt Iodization Machine

Purpose: To add iodine to the salt for fortification.

Process: An iodizing machine adds a controlled amount of iodine during the salt’s transfer from the centrifuge to the drying bed.

>>>

Packaging - Salt Packing Machine

step8

Packaging - Salt Packing Machine

Purpose: To package the finished salt for distribution. Process: The dried and iodized salt is packed into bags or containers using automated packaging machines.

Specifications

more information about salt and soap production lines

Model: Mechanical Salt Production Line

Capacity: 0.5 to 50 tons/hour (customizable)

Materials: Stainless steel, corrosion-resistant materials

Power Supply: 380V/50Hz (customizable to local standards)

Salt Processing Machinery

Get in Touch with Us

Have questions or need more information about our salt production solutions? Our team is here to assist you with tailored advice and expert support. Reach out today to learn more about how we can help you achieve top-quality production.

Why Choose RSE Salt Production Line?

High Purity Salt

Multi-stage washing and final iodization ensure the salt meets high purity and quality standards. The refined salt has high purity, a shiny appearance, good free liquidity, and stable iodine content.

Efficient Operation

Each stage of the process is designed for efficiency, reducing processing time and operational costs. Low loss, the loss of NaCl is under 10%.

Customizable Capacity

The production line can be tailored to different capacities (from 0.5 to 50 tons/hour) to meet specific production needs

Durable Construction

Engineered with high-quality, corrosion-resistant materials for long-term reliability and minimal maintenance. The equipment offers a long service life and is easy to operate and maintain.

Integrated Iodization

Seamlessly adds iodine to the salt, meeting nutritional standards without additional processing steps.

Ready to move?

Get a quote now !

Advanced Technology

Combination of Technologies: The integration of wet crushing, dry crushing, and advanced washing methods significantly improves the quality of the salt.