Our detergent powder production line, as a benchmark work in the industry, not only leads the innovative trend in the field of detergent production but also establishes a new height in the development of the industry with its excellent efficiency and environmental protection concept. This production line integrates the solid foundation of civil engineering, the intelligent control of electrical systems, the real-time monitoring of precision instrumentation, the highly automated production process, and the perfect fusion of advanced equipment manufacturing technology, forming an overall system with high efficiency, synergy and intelligent operation.

Key Features

Integrated Design

- Comprehensive Integration: Combines civil work, electrical systems, instrumentation, automation, and equipment fabrication into a single, streamlined solution.

- Seamless Operation: Ensures all components work together efficiently, reducing operational complexities and enhancing overall production efficiency.

Core Competency

- Advanced Technology: Utilizes cutting-edge technology and innovation to deliver high-quality detergent powders.

- Global Leadership: Our technology is at the forefront of industry advancements, ensuring competitive performance and reliability.

Environmental Protection

- Eco-Friendly Techniques: Incorporates techniques and practices designed to minimize environmental impact, including energy-efficient processes and waste reduction systems.

Professional Commissioning Service

- Expert Support: Our team of professionals provides comprehensive commissioning services, ensuring the production line is set up correctly and operates smoothly.

- Training and Support: Offers training and ongoing support to ensure optimal performance and ease of operation.

Plants Advantage

- Manual or Automatic Systems: Choose between manual or fully automatic computer-controlled systems based on your production needs and preferences.

- Customization: Adaptable to various production requirements, providing flexibility for different types of detergent powders.

Packaging and Shipping

- Packaging Details: The equipment is packed in wooden crates and other sea-worthy materials to ensure safe transportation.

- Port of Shipment: Ships from China, ready for global distribution.

Main Components

- Mixing System:

- High-Efficiency Mixers: Blend detergent ingredients to achieve uniformity and consistency in the powder.

- Granulation Unit:

- Granulators: Convert the mixed detergent powder into granules of desired size and shape.

- Drying System:

- Dryers: Remove moisture from the granulated detergent powder to achieve the desired dryness and flowability.

- Cooling System:

- Coolers: Cool the dried granules to prevent clumping and ensure optimal quality.

- Screening and Sorting:

- Screeners: Remove any oversized or undersized granules, ensuring uniformity in the final product.

- Packaging System:

- Packagers: Automatically package the finished detergent powder into various sizes of bags or containers.

- Control Panel:

- Automation: Advanced PLC and computer-controlled systems for monitoring and managing the production process.

Operating Principle

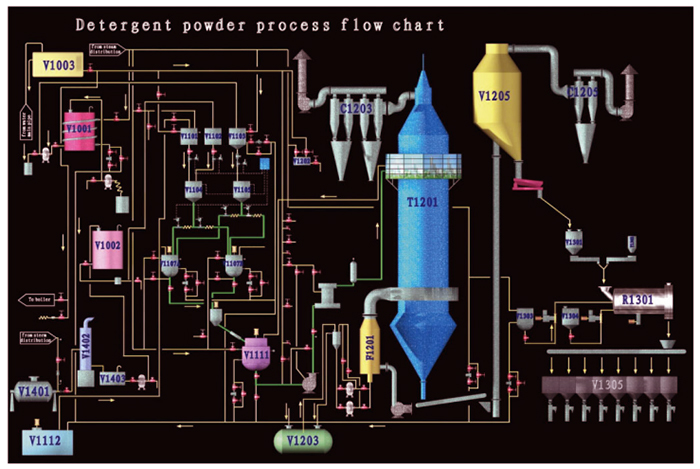

The working principle of the detergent powder production line is a well-designed process aimed at achieving an efficient, precise and environmentally friendly transformation from raw material to finished product. The following is a detailed topology of the working principle of the line:

Raw material preparation and mixing stage:

The starting point of the line is the preparation and mixing of the raw materials. In this stage, a wide range of selected detergent raw materials, such as surfactants, auxiliaries, fillers and flavors, are fed into large-scale mixing plants in strict proportions. These mixing machines are designed with advanced stirring technology and uniform distribution to ensure that all raw materials can be fully and evenly mixed together, laying a solid foundation for the subsequent steps. During the mixing process, parameters such as temperature, humidity and mixing speed are precisely controlled to ensure the stability and consistency of the mixture.

Pelletizing and molding stage:

The homogeneously mixed raw material then enters the pelletizing and moulding stage. In this stage, the mixture is extruded into pellets of specific size and shape by means of equipment such as special pelletizers or extruders. The size, shape and density of these pellets are carefully designed to meet the performance requirements of the detergent product and market demand. During the pelletizing process, key parameters such as temperature, pressure and speed are strictly monitored and adjusted to ensure consistent and stable pellet quality.

Drying and Dehydration Stage:

After granulation, the granules contain a certain amount of moisture, which needs to be dewatered by drying equipment. The drying equipment usually adopts hot air circulation or vacuum drying technology, utilizing high temperature air or a vacuum environment to quickly remove the moisture in the granules. During the drying process, parameters such as temperature and time are precisely controlled to avoid overheating and deformation or scorching of the pellets, while ensuring that the moisture content meets product standards. The dried pellets are harder and more stable for subsequent storage and transportation.

Cooling, screening and sorting stage:

The temperature of the dried pellets is high and needs to be cooled down by cooling equipment. The cooled particles enter the screening and classification stage, removing impurities, broken particles and particles that do not meet the specifications through vibrating screens, airflow classifiers and other equipment. At the same time, the particles are classified according to their size, density and other characteristics to ensure the uniformity and consistency of the final product. The application of advanced testing technology and automated equipment during the screening and classification process improves production efficiency and product quality.

Packaging and Distribution Stage:

Finally, the finished detergent powder after screening and sorting is sent to the packaging equipment for encapsulation. The packaging equipment automatically completes the processes of measuring, sealing and labeling according to the product specifications and market demand, ensuring that each package meets the hygiene standards and quality requirements. After packaging, the finished detergent powder is sent to the warehouse for storage and transported to various markets according to the distribution plan. During the distribution process, we focus on logistics management and customer service to ensure that the products can be delivered to customers in a timely and accurate manner.

Tips for Installation and Maintenance

Installation Tips

- Site Preparation: Ensure the installation site is clean, dry, and has sufficient space for the equipment and maintenance access.

- Electrical and Plumbing Setup: Connect the equipment to a stable power supply and ensure all plumbing connections are properly installed.

- Initial Setup: Follow the manufacturer’s guidelines for initial setup and calibration of the control systems.

Maintenance Tips

- Regular Cleaning: Clean the machinery regularly to prevent residue buildup and maintain optimal performance.

- Component Inspection: Periodically inspect components for wear or damage and replace them as needed.

- Lubrication: Regularly lubricate moving parts to reduce wear and ensure smooth operation.

Customer Testimonials

James Roberts, Production Manager: “The Detergent Powder Production Line has streamlined our operations and significantly improved product quality. The integration of advanced technology has made a big difference.”

Linda Wang, Operations Director: “We are very pleased with the performance of this production line. The flexibility between manual and automatic systems has been very beneficial for our production needs.”