HANDMADE SOAP FINISHING LINE

Description:

Handmade soap production line is a production line integrating traditional handicrafts and modern industrial technology. It takes the stainless steel reactor as the core equipment, and through a series of fine processes, it transforms the natural raw materials into handmade soaps with colorful and different shapes. These soaps are not only exquisite in appearance, but also excellent in quality, and are very popular in the market.

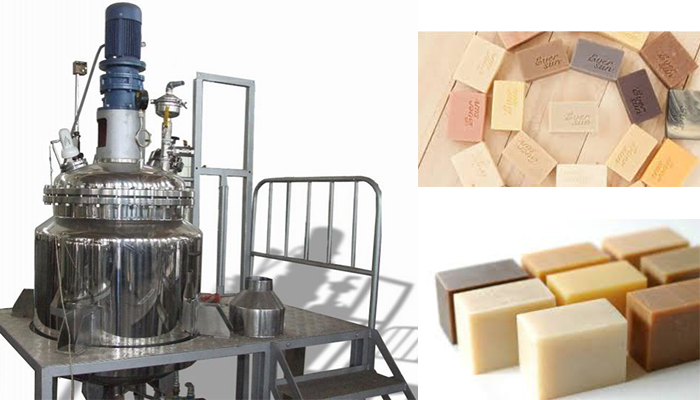

Appearance:

While the Handmade Soap Production Line blends traditional craftsmanship with modern industrial elements, its appearance presents an atmosphere of warmth and sophistication. The core equipment, the industrial grade stainless steel reactor, shows professionalism and durability with its sharp contrast of blue top and silver bottom. The well-designed valves and pipes on the reactor not only meet the needs of the production process, but also reflect the fineness and rigor of the craftsmanship. The small metal mixer is silently assisting at the side, adding a touch of technology to the whole production line.

Composition of the production line:

Although the handmade soap production line is named “handmade”, it actually combines the essence of mechanization and manual operation. In addition to the stainless steel kettle and mixer mentioned above, the production line also includes a number of functional areas such as raw material preparation area, mixing and blending area, molding and cooling area, and packaging area. Each area is equipped with professional equipment and tools to ensure that every step from raw material placement to finished product packaging can be precisely controlled.

Finished Product Description:

The handmade soap blocks produced by the production line each carry the craftsman’s heart and creativity. They not only come in a wide variety of colors, from warm brown to fresh beige to light green, which meets the aesthetic needs of different consumers; but also come in different shapes, ranging from regular squares to more creative shapes, which shows the unique charm of handicrafts. Each bar of soap may also be printed with a brand logo or handwritten blessings, adding more emotional value to the product.

Function:

The main function of the handmade soap production line is to transform natural raw materials into high quality handmade soap. By precisely controlling parameters such as temperature, pressure and time in the reactor, as well as using high-quality raw materials and unique formulas, the production line is able to produce handmade soaps with a wide range of effects such as moisturizing, cleansing and soothing. These soaps are not only suitable for daily use, but also have certain health effects, which are popular among consumers.

After-sales service:

We understand the importance of after-sales service to our customers, so we provide comprehensive after-sales support for our handmade soap production line. From equipment installation and commissioning to daily maintenance, we will send professional technicians to carry out the whole tracking service. At the same time, we also provide 24-hour online customer service, at any time to answer customer problems encountered in the process of use. For any production interruption caused by equipment failure, we will quickly respond and provide solutions.

Technical Support:

To ensure that our customers are able to take full advantage of the handmade soap production line’s features and continuously optimize their production processes, we offer comprehensive technical support services. This includes regular technical training, remote troubleshooting, and equipment upgrades and modifications. Our technical team consists of experienced engineers and R&D personnel who are not only familiar with the technical details of the production line, but are also able to provide customized solutions based on the customer’s actual needs.

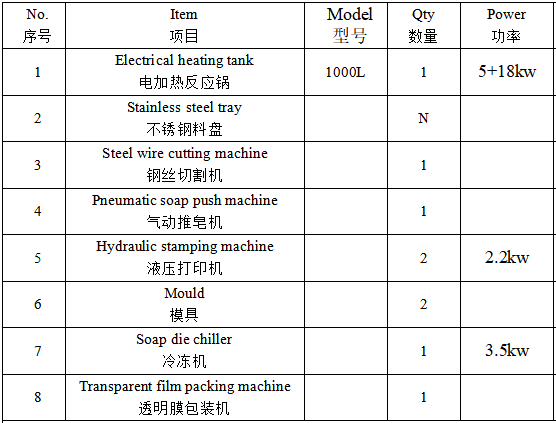

The following is an introduction to the component machines of handmade soap production line and their parameters:

This handmade soap production line contains a series of key equipment from heating and mixing of raw materials to packaging of finished products, and the equipment work in synergy with each other to realize the efficient and automatic production of handmade soap.

1. Electrically heated reaction pot

Function: Mainly used for heating and mixing reaction of soap raw materials, it is one of the key equipments in soap production process. Its large capacity design can meet the demand of mass production, while the high power ensures rapid and uniform heating and reaction.

2. Stainless steel material tray

Function: Used for holding and transporting soap raw materials or semi-finished products, stainless steel material ensures the hygiene and safety of the products.

3. steel wire cutting machine

Function: After the soap is molded, the soap is cut accurately to meet the needs of different specifications and shapes.

4. Pneumatic Soap Pusher

Function: Push the soap block or bar into the next process, such as cutting or packing, by pneumatic principle, which improves the automation of the production line.

5. Hydraulic press (Note: the original “hydraulic printer” should be “hydraulic press” misspelled)

Power: 2.2kw

Function: Stamping and molding of soap by hydraulic pressure, which can produce various shapes of soap, such as square, round, and so on.

6. mold

Function: Used in conjunction with the hydraulic press to determine the final shape and size of the soap.

7. Soap die chiller

Power: 3.5kw

Function: Cooling soap after molding to make it cure quickly for subsequent cutting and packaging.

8. Transparent film packaging machine

Function: Automatically wraps the cooled and cut soap blocks or bars in transparent film, which improves the aesthetics and protection of the product, as well as facilitates sales and storage.