Flower soap is new generation, portable, green and fashion soap. It’s as thin as paper, which is name by this feature. It’s the necessary for high quality modern life. It is the potential rising industry in 21ST century.

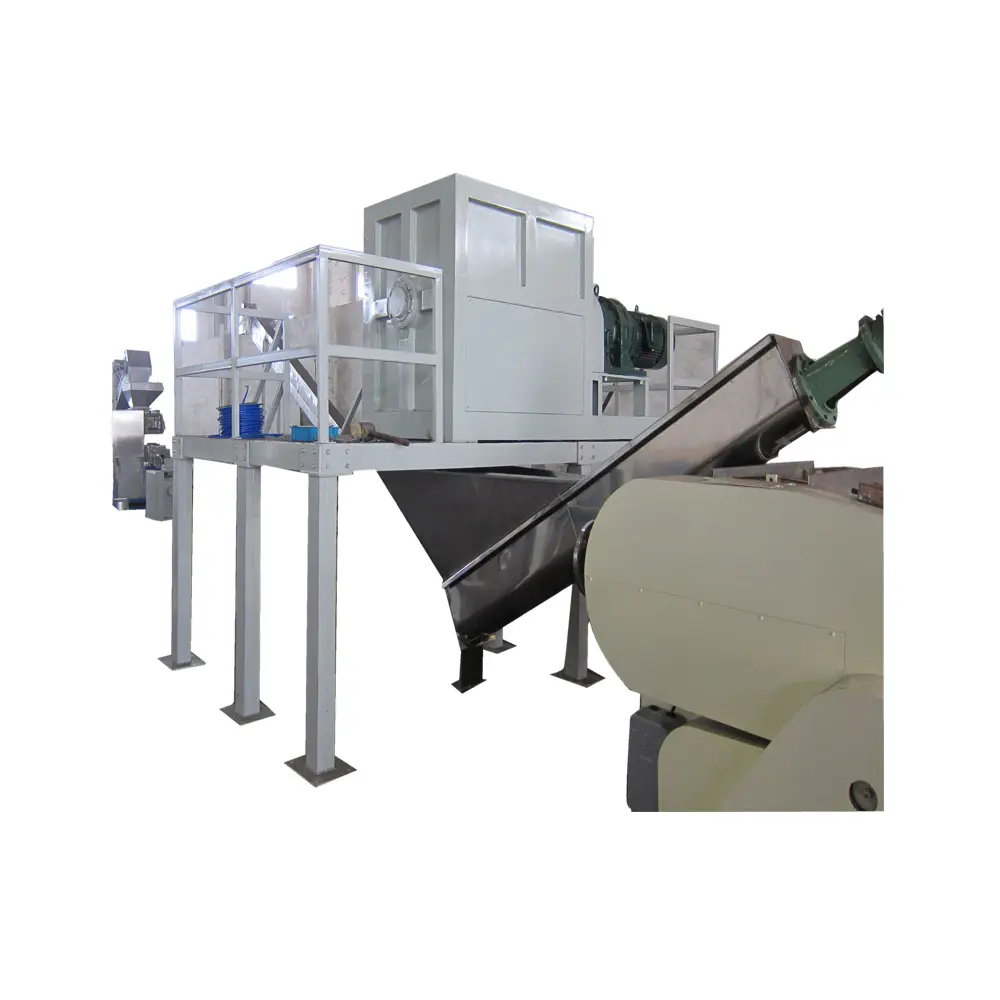

Our toilet paper soap manufacturing machine integrates the most advanced design concepts and manufacturing technologies, and realizes efficient transformation from raw material input to finished product output through precise control system and optimized production process. The machine is capable of steadily producing soap flakes that are uniform in texture and dissolve quickly, ensuring that each flake meets the established quality standards. This efficient production capacity not only improves production efficiency, but also greatly reduces production costs, bringing significant economic benefits to manufacturers.

Thin and soluble, convenient and hygienic

The highlight of toilet paper soap is its lightweight and dissolvable nature. This design makes the soap flakes easy to carry and take up little space, making them ideal for use in travel kits or outdoor emergencies. At the same time, it is convenient and hygienic to use as it simply tears off a piece and dissolves in water without rinsing. For the hotel industry, this single-use soap not only improves the cleanliness and comfort of guest rooms, but also reduces the risk of cross-contamination that may be brought about by the repeated use of traditional soap.

Environmental protection and energy saving, green production

In today’s increasingly aware of environmental protection, toilet paper soap manufacturing machinery also fully take into account environmental factors. Equipment in the production process adopts the design concept of low energy consumption and low emissions, effectively reducing energy consumption and environmental pollution. In addition, because the soap flakes are light and easy to degrade, so the waste generated in the process of use is also relatively small, which is conducive to the realization of the sustainable use of resources and the protection of the environment.

Ease of use and low maintenance reduces costs

In order to reduce the user’s operating difficulties and maintenance costs, the toilet paper soap manufacturing machine is designed with a special focus on ease of use and low maintenance. The machine adopts an intuitive operation interface and humanized design layout, which enables the operator to easily get started and quickly master the operation skills. At the same time, the key components inside the equipment are made of high-quality materials, wear-resistant and durable and easy to replace and maintain, greatly reducing the user’s maintenance costs and time costs.

Flow chart:

Ingredient preparation–mixing (with heating) — add color and perfume — forming (with heating)

— cutting –packing

The Paper Toilet Soap Making Machinery is designed to provide a comprehensive solution for modern soap manufacturing plants. Its advanced technology ensures high efficiency and superior product quality, making it an essential tool for paper soap producers.

The Flower Soap Making Machine has brought significant economic benefits to manufacturers with its high production capacity of 300 kilograms per hour. What’s more remarkable is that the machine saves space resources greatly while producing efficiently – it occupies an area of only about 300 square meters, which greatly reduces the land occupation compared to traditional soap making equipment, providing strong support for the sustainable development of the enterprise. In addition, it can be easily operated by only 3 workers (excluding packaging workers), which greatly reduces labor costs and improves production efficiency.

Key Features

High Efficiency

- High Production Rate: Capable of producing large volumes of paper soap sheets, meeting high market demand efficiently.

- Automated Operation: Fully automated process from raw material feeding to final paper soap formation, reducing labor costs and increasing productivity.

Superior Quality

- Consistent Output: Advanced coating and drying technologies ensure uniform texture and quality of each paper soap sheet.

- High-Quality Molds: Durable and precise molds create well-formed soap sheets with consistent thickness and size.

User-Friendly Design

- Easy to Operate: Intuitive control panel with user-friendly interface simplifies machine setup and operation.

- Quick Changeover: Fast and easy changeover between different soap formulations and sizes, allowing for flexible production.

- Low Maintenance: Durable construction with high-quality materials reduces the need for frequent maintenance and ensures long-term reliability.

Versatile Application

- Multiple Soap Types: Suitable for the production of various types of paper soap, including different fragrances and formulations.

- Customizable: Adjustable settings and interchangeable molds allow for the production of customized paper soap sheets to meet specific branding requirements.

Customer Testimonials

Sarah Brown, Travel Product Manufacturer: “This machine has enabled us to expand our product line with high-quality paper soap sheets. It’s efficient and easy to use, and the output quality is consistently excellent.”

David Lee, Hospitality Supplier: “The paper soap making machinery has been a great addition to our production line. It’s reliable, low-maintenance, and allows us to meet the increasing demand for travel-friendly hygiene products.”