The Salt Washing Machine is an essential piece of equipment in the salt processing industry, designed to purify and enhance the quality of crude salt. It utilizes a multi-stage washing process to remove impurities, ensuring that the final product meets high standards of purity and quality. The machine is suitable for processing various types of salt, including sea salt, lake salt, and rock salt.

Washing Stages and Their Functions

- First Screw Washing

- Purpose: The initial cleaning of crude salt to remove large impurities and dirt.

- Process:

- Mechanism: Crude salt is fed into a horizontal screw conveyor where it is mixed with water. The rotating screw agitates the salt and water, washing away the bulk of surface contaminants.

- Design Features: The screw conveyor has a robust, corrosion-resistant construction and adjustable speed settings to handle varying salt loads and washing requirements.

- Second Screw Washing

- Purpose: Provides a secondary wash to remove finer impurities left after the first stage.

- Process:

- Mechanism: A second screw conveyor, often with a different pitch or design, continues the washing process. This stage ensures that any remaining contaminants are further washed away.

- Design Features: Enhanced washing efficiency with improved water flow and agitation mechanisms compared to the first stage.

- Stand-up Stirring Washing

- Purpose: Provides a more vigorous and thorough cleaning action.

- Process:

- Mechanism: Salt is placed in a vertical tank equipped with mechanical stirring blades. The salt is continuously stirred and agitated, allowing for deeper penetration of cleaning water and more effective removal of residual impurities.

- Design Features: Includes adjustable stirring speeds and blade configurations to optimize cleaning performance.

- Countercurrent Washing

- Purpose: The final stage of washing, designed for optimal impurity removal and thorough rinsing.

- Process:

- Mechanism: Salt moves through a series of tanks or channels where water flows in the opposite direction to the movement of the salt. This countercurrent flow maximizes contact between the salt and water, effectively removing any remaining impurities.

- Design Features: Designed to ensure complete rinsing with minimal water usage and effective impurity removal.

The four washing is as follows:

1. First Screw washing

2. Second screw washing

3. Stand-up stirring washing

4. Countercurrent washing

Main Components

- Screw Conveyor

- Function: Transports and washes salt through a screw-driven mechanism.

- Features:

- Material: Made from stainless steel or other corrosion-resistant materials.

- Adjustability: Speed and pitch can be adjusted to accommodate different processing needs.

- Stand-up Stirring Tank

- Function: Provides intensive mixing and washing of salt.

- Features:

- Material: Constructed from high-quality stainless steel.

- Stirring Blades: Equipped with adjustable blades for effective agitation.

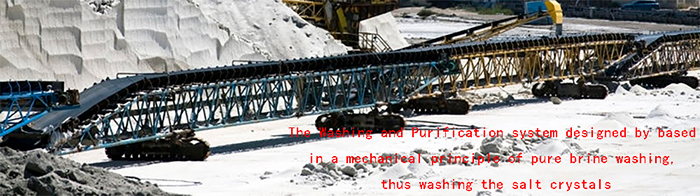

- Countercurrent Washing System

- Function: Ensures thorough rinsing of salt with countercurrent water flow.

- Features:

- Design: Multiple tanks or channels with controlled water flow.

- Material: Durable construction to handle continuous water flow and salt processing.

- Control System

- Function: Manages washing stages and operational parameters.

- Features:

- Control Panel: User-friendly interface for adjusting settings.

- Automation: Optional automated controls for enhanced efficiency and consistency.

Advantages

- Enhanced Purity:

- Benefit: The multi-stage washing process ensures high purity by effectively removing a wide range of impurities.

- Efficiency and Consistency:

- Benefit: Each washing stage is designed to optimize impurity removal, resulting in consistent product quality.

- Customizable Settings:

- Benefit: Adjustable parameters allow for tailoring the washing process to different types of crude salt and desired end product specifications.

- Energy and Water Efficiency:

- Benefit: Advanced design reduces water consumption and energy usage, making the process more sustainable.

- Durable Construction:

- Benefit: Built with high-quality materials to withstand the harsh conditions of salt processing and ensure long-term reliability.

Applications

- Salt Processing Plants: Ideal for initial and final washing stages of salt processing.

- Food Industry: Suitable for producing high-purity salt used in food products.

- Chemical Industry: Used in manufacturing processes requiring purified salt.

Installation and Maintenance

- Installation:

- Site Requirements: Ensure a clean, level area with adequate space for equipment and operation.

- Setup: Follow manufacturer guidelines for assembly and calibration of the washing stages.

- Maintenance:

- Routine Cleaning: Regularly clean the washing components to prevent the buildup of salt and residue.

- Inspection: Periodically check and maintain screw conveyors, stirring mechanisms, and countercurrent systems for wear and tear.

- Lubrication: Apply lubrication to moving parts as needed to ensure smooth operation.

Why Choose Our Salt Washing Machine?

Our Salt Washing Machine offers a robust and efficient solution for achieving high-purity salt. With its multi-stage washing process and customizable features, it ensures thorough cleaning and optimal performance for various salt processing applications.

Contact:

Ms. Lotus Peng

Mobile/whatsapp/wechat: +86 13917675139