SOAP COMPLETE LINE FROM OIL AND FAT

(CAPACITY:500~3000kg/H)

We understand the importance of technological innovation in driving the development of the industry, therefore, in the field of oleo soap production, we have always regarded technological research and refinement as the core driving force. Our team gathers elites and experts in the industry, and is committed to exploring more efficient, environmentally friendly and intelligent production solutions to meet the growing and diversified production needs of our customers.

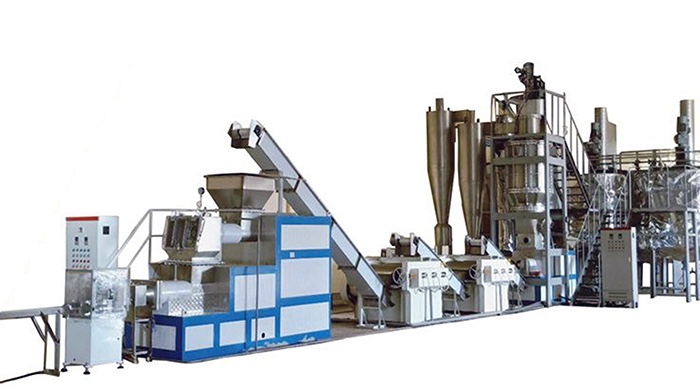

Grease soap production line, as our star product, not only integrates the latest production process and automation control technology, but also takes into full consideration the flexibility and expandability of the equipment. From the precise proportioning and mixing of raw materials, to heating and melting, saponification reaction, to molding and cutting, packaging and warehousing, each step is carefully designed and optimized to ensure stable and reliable product quality and significant increase in production efficiency.

We know that the stable operation of the equipment is an important guarantee for customers to have worry-free production. Therefore, in terms of after-sales service, we have established a perfect service system, including professional installation guidance, detailed operation training, timely troubleshooting and repair, as well as continuous technical support and upgrade services. We promise that no matter when and where, as long as customers have the need, our service team will respond quickly to provide customers with a full range of one-stop solutions.

When discussing the technical advantan technology of grease soap, to provide customers around the world with more high-quality, efficient and reliable production equipment and solutions, and work together to create a better ges of our grease soap production line, we must mention its excellent performance in terms of smoothness of operation, especially its excellent “no lag” characteristics. This characteristic comes from our fine design and optimization of the internal mechanical structure of the equipment, as well as the deep integration and customization of the automation control system.

First of all, we have adopted high-quality transmission components and precision bearing systems to ensure the stability and durability of the equipment under high-speed operation. At the same time, the advanced dynamic balancing technology effectively reduces the vibration and noise of the equipment, which further enhances the comfort and productivity of the production environment. This design not only reduces the equipment failure rate, but also greatly extends the service life of the equipment, saving customers long-term maintenance costs.

Secondly, our automation control system adopts high-performance processors and optimized algorithms, which are able to monitor various parameters in the production process in real time and make quick adjustments according to the actual situation. This intelligent control not only improves production accuracy and consistency, but also allows the line to cope with complex production demands with greater ease. Even under high loads, the line maintains smooth operation and avoids stuttering or stalling, ensuring the continuity and efficiency of the production line.

In addition, we emphasize the seamless integration and synergy between equipment. Through advanced communication protocols and data exchange technologies, we have realized close cooperation and information sharing between all parts of the production line. This highly integrated production method not only improves overall production efficiency, but also provides customers with more flexible and diverse production options.

To sum up, the technical advantages of our grease soap production line are not only reflected in its excellent “non-lagging” characteristics, but also in its comprehensive optimization of production efficiency, product quality, operational stability and intelligent control. We firmly believe that these technical advantages will bring our customers a more efficient, reliable and intelligent production experience, and help them stand out in the fierce market competition.

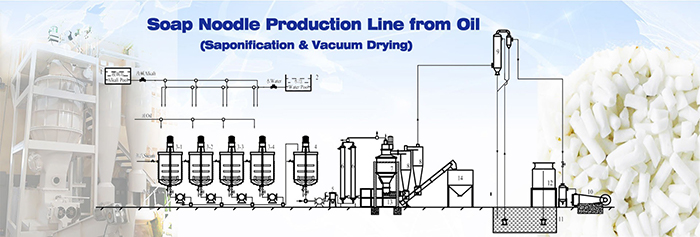

Saponification, vacuum drying process equipment list

Finishing line equipment list