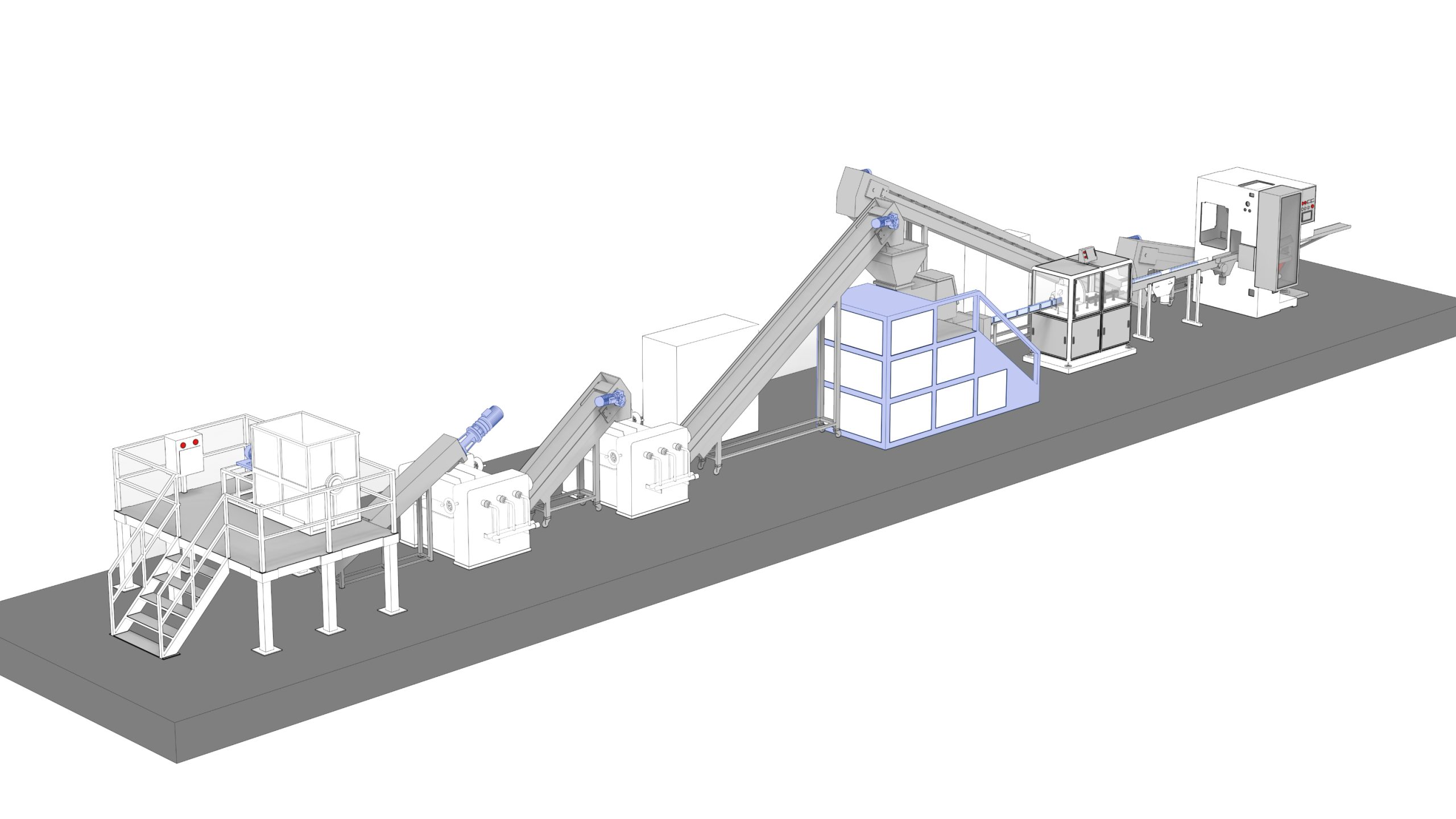

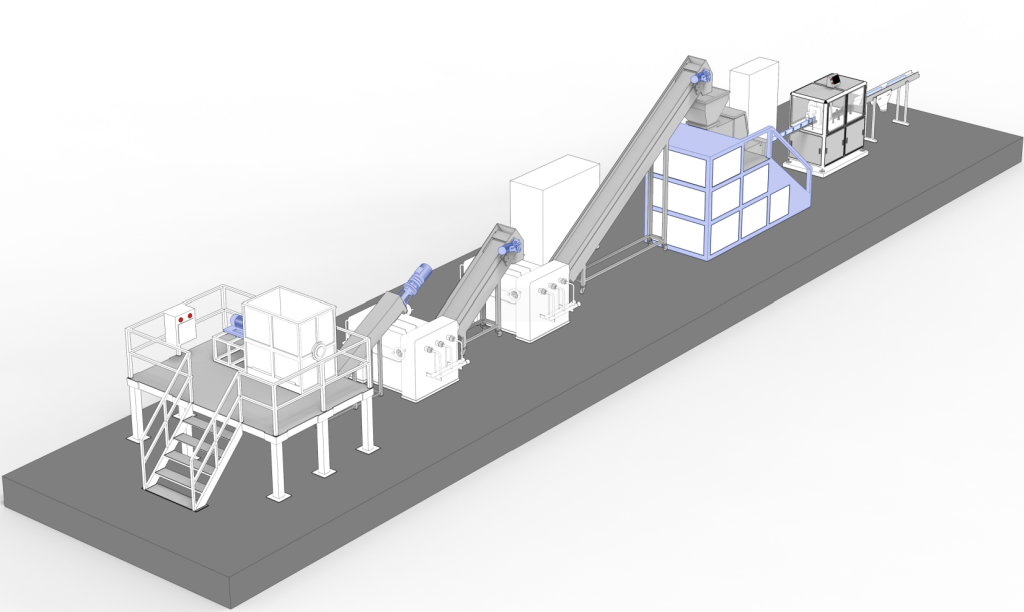

Toilet Soap Finishing Line

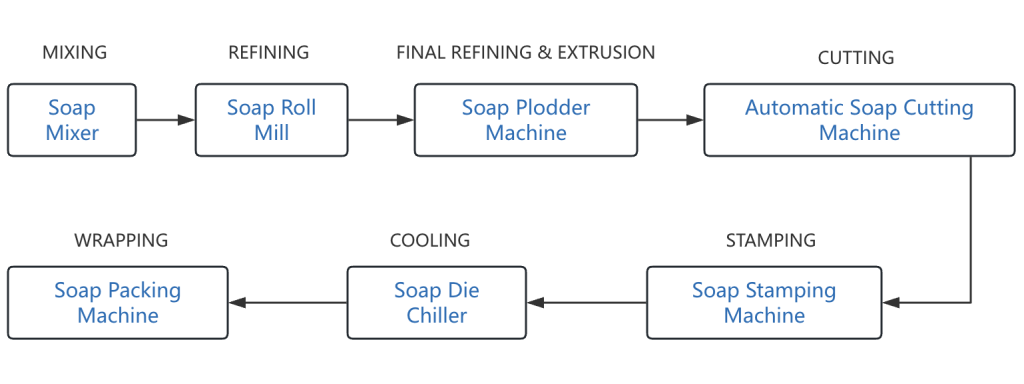

The toilet soap finishing production line begins with soap noodles and progresses through a mixer, milling equipment, and vacuum plodder, followed by cutting, stamping, and other finishing processes. The final soap product is smooth, dense, resistant to cracking, and features a bright appearance.

Toilet Soap Finishing Line

The capacity of 500-2000kg/h is the normal range of soap production lines required in many soap manufacturing countries. We can provide any range of this according to the client’s requirements. We provide the service of sending technicians for guidance on installation, commissioning, and training.

Comprehensive Solution for Laundry Soap

Our soap production lines are designed with the diversified needs of our customers in mind. Whether it is a small-scale artisanal workshop or a large-scale industrialized production, we can offer tailor-made solutions. Variations in production capacity from 500kg/h to 2000kg/h can be easily realized by adjusting the configuration and number of equipment, ensuring that production efficiency closely matches market demand.

Soap Mixer : One mixing shaft with two mixing paddles, is driven by the motor through the gear box and rotating continuously to mix soap noodles, flakes are mixed with all kinds of liquid and solid ingredients inside the mixer chamber. After the mixing, products are discharged through air cylinder controlled discharging door.

Soap Roll : Mill The Three Roll Mill is used for soap refining in soap making machine. Three rolls are horizontally placed with different rotating speeds. The refining function is achieved by pressing and squeezing force between the adjacent rolls.

Soap Plodder Machine : The duplex vacuum plodder is very important in the soap making machines.This machine has two stages, driven by independent transmission system. The first plodder is acting as a simplex refining to make soap pellets in the vacuum condition. In the final plodder, the soap is pressed and extruded out in billets through the orifice to feed the downstream cutter or stamper.

Automatic Soap Cutting Machine : Apply stainless steel knife blade, MITSUBISHI frequency converter, servo motor, servo controller, OMRON PLC and rotary coder, Germany Siegling conveyer, 7inch color touch screen.

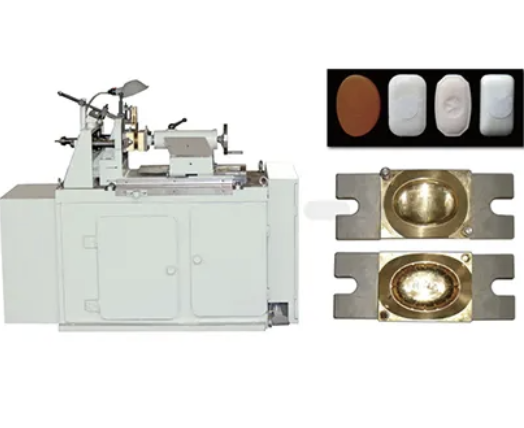

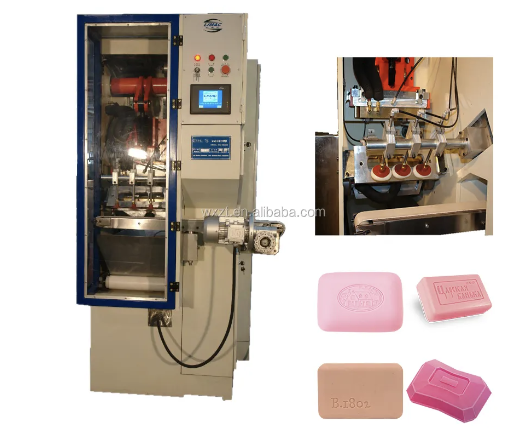

Soap Stamping Machine : In the stamping process, each soap bar is embossed or molded with the brand logo or design using a automatic soap stamping machine, giving the product a finished and professional appearance.

Soap Die Chiller : The soap die chiller is to chill the soap die (mould) in the soap making machine line. It can refrigerate the cooling liquid rapidly, and transport the cooling liquids to the heat exchanger by the pump.

Soap Packing Machine : This machine is used to package finished soaps at the end of production. It can create various types of packaging using a range of materials.

Soap Production lines with different capacities

Lab Soap Machine/ Pilot Soap Machine (make soap no more than 100g)

100kg/h or 150kg/h Soap Machine

Get in Touch with Us

Have questions or need more information about our soap production solutions? Our team is here to assist you with tailored advice and expert support. Reach out today to learn more about how we can help you achieve top-quality production.

What’s your story? We’ll help you tell it.

Team Support

Frequently Asked Questions

Networking